The Future of Partial Dentures

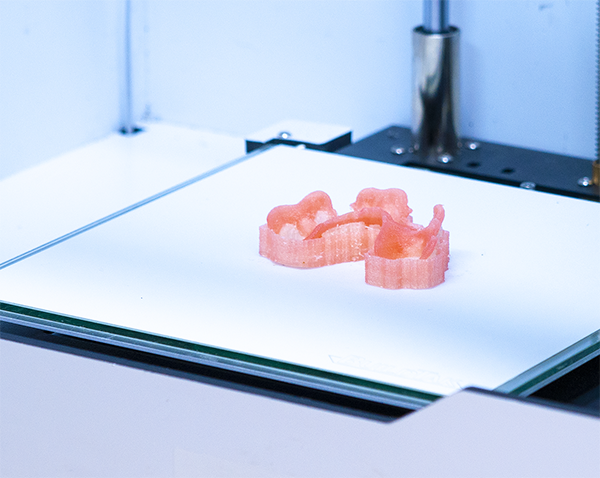

Partial design starts with impressions, either physical or intraoral scans, in the same way as digital dentures. The design is accomplished in 3Shape software and sent to a unique printer capable of using fiberglass infused nylon made for this process by Valplast. The printer uses a process called "fused deposition modeling" or FDM. This is different than the resin based printing used in the denture manufacturing process. A thin filiment is deposited on a platform by pressing it through a heated extruder. As the platform moves the gingiva base material is is built layer by layer. The final base is then processed and polished.

Digital denture design and 3d printing allows us to create an infinate range of teeth types, anatomy and positions. Traditional designs relied on using "Teeth cards" with a limited range of stock choices. Every aspect of a design is custom matched to the doctor (and patients) requirements. Occlusion is adjusted digitally to achieve ideal group function.

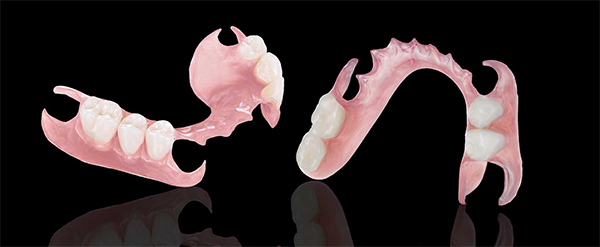

From flippers to multitooth upper and lower arches, we can provide designs that fit every application. Because they are "digital" and 3D printed, they fit perfectly and are comfortable with little adjustment at delivery.