Old School restorations vs. CADCAM

The transition from analog to digital workflow has required practitioners to adopt a new mind-set on perperation requirements. Hopefully this page will show these requirements from the perspective of a CADCAM based digital lab. Benefits of following these new protocals will mean much better final restoration quality. Old school labs will be all but replaced by this technology. These requirements can be adopted by all practitioners using tradtional impressions or intraoral scanners.

CAM Production Insights

Milling restorations in a lab (or office) is done using burrs of diferent sizes. The size of the burr determines the final level of detail. The smallest burr diameter and tip shape will limit the edge detail on the intaglio. For example a .5mm diameter burr cannot follow the profile of a knife edge prep. A round profile extending past the prep edge has to be created to allow seating of the restoration

Prep adjustment for ideal restoration

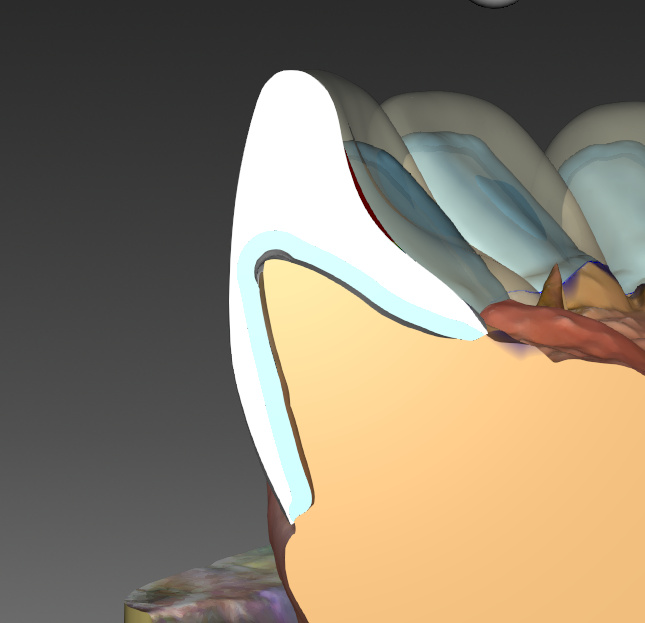

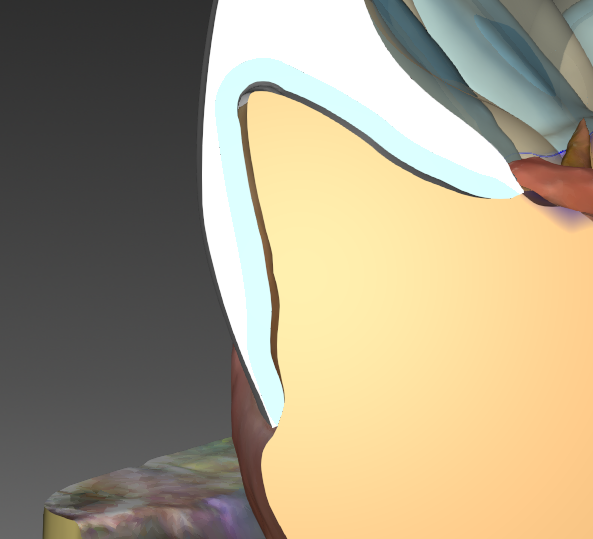

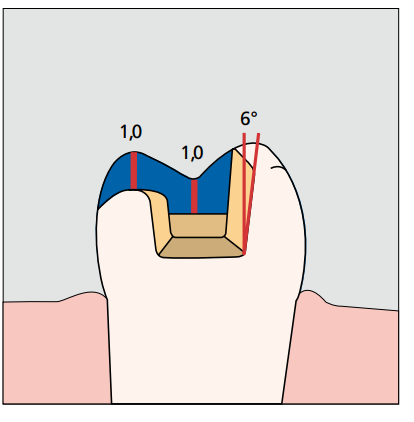

In the figure above the blue shaded area defines the minimum thickness for the material, in this case E.max. The contour of the facial area of this crown will have to be bulked in the area where the minimum thickness protrudes. In this case adding that thickness will take away from the ideal aesthetics.

In the figure below you can see that rounding this edge is enough to achieve minimum thickness without reducing the facial area of the prep. You can also see that this reduction does not reduce retention surface, and in fact improves it.

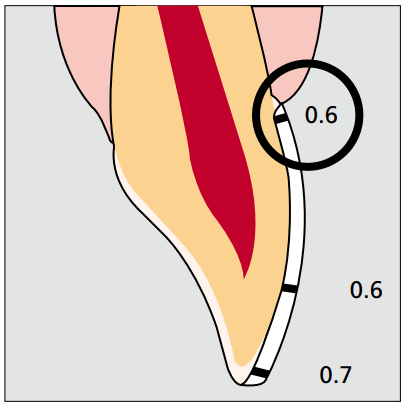

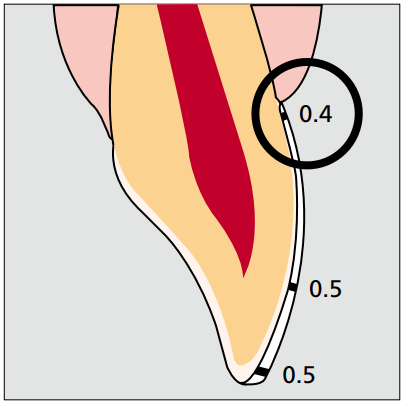

Margin limitations in CAM

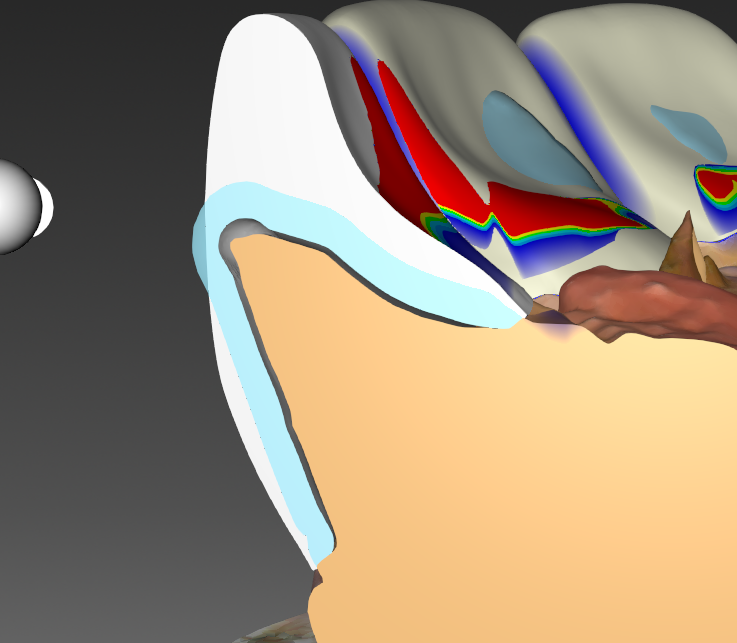

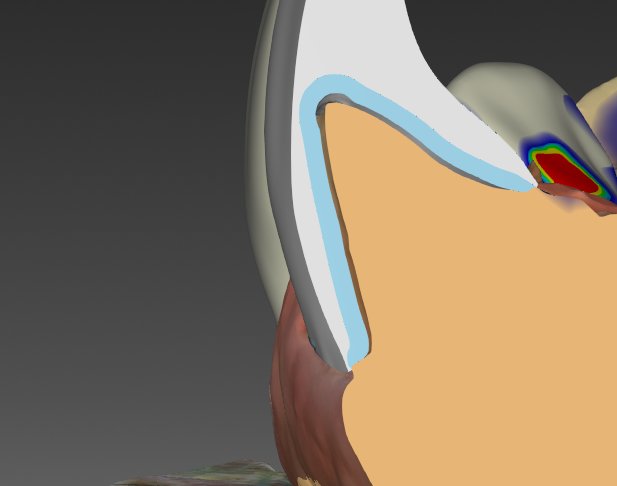

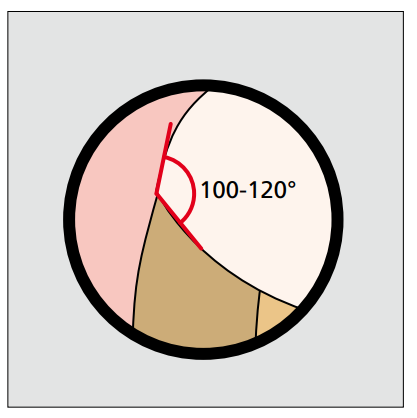

The minumum thickness limitations, because of burr diameter, also affects the margin of milled restorations. In the figures below you can see the effect on the three common margin types: shoulder, chamfer, and feather. The blue area protruding from the margin area of the feather example will require additional material which will negatively affect the emergence profile.

We prefer shoulder margins if possible. They make defining the margin much easier and reduce chipping in the milling process.

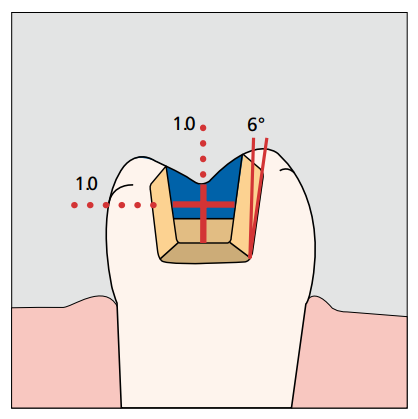

Recomended preparation dimensions for veneers.

Below you will find the ideal and minimum dimensions for veneers. The ideal material for thin veneers is E.max

Recomended preparation dimensions for inlay / onlays (E.max).

We only make inlays and onlays from E.max materials.

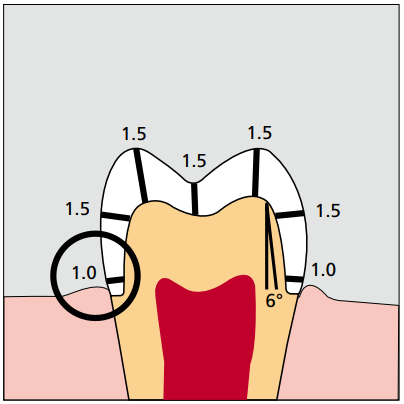

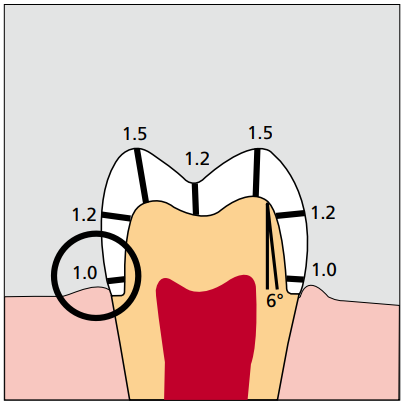

Recomended preparation dimensions for posterior crowns.

Below are the recomended preperations for E.max and zirconia crowns (respectively) Note that the same recomendations for cusp profiles and margins apply. Overly "pointy" cusp tips will reduce the restoration thickness. This may require opposing reduction. We can manufacture thinner restorations, but this increases the risk of fracturing significantly.