The Digital Workflow

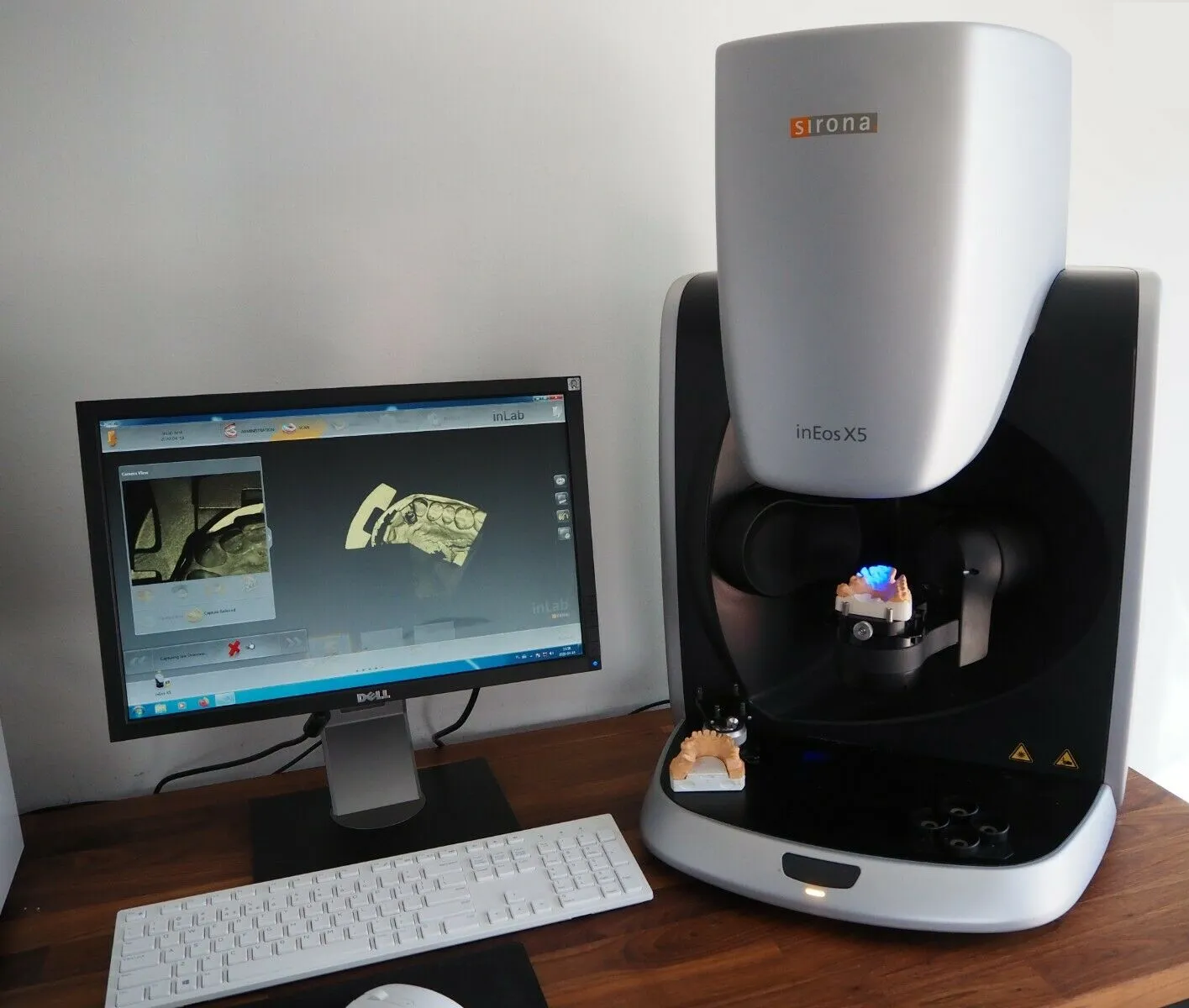

All designs start with scanning. Either an intraoral scan performed chairside, or a traditional stone model scanned in the lab.

All designs start with scanning. Either an intraoral scan performed chairside, or a traditional stone model scanned in the lab.

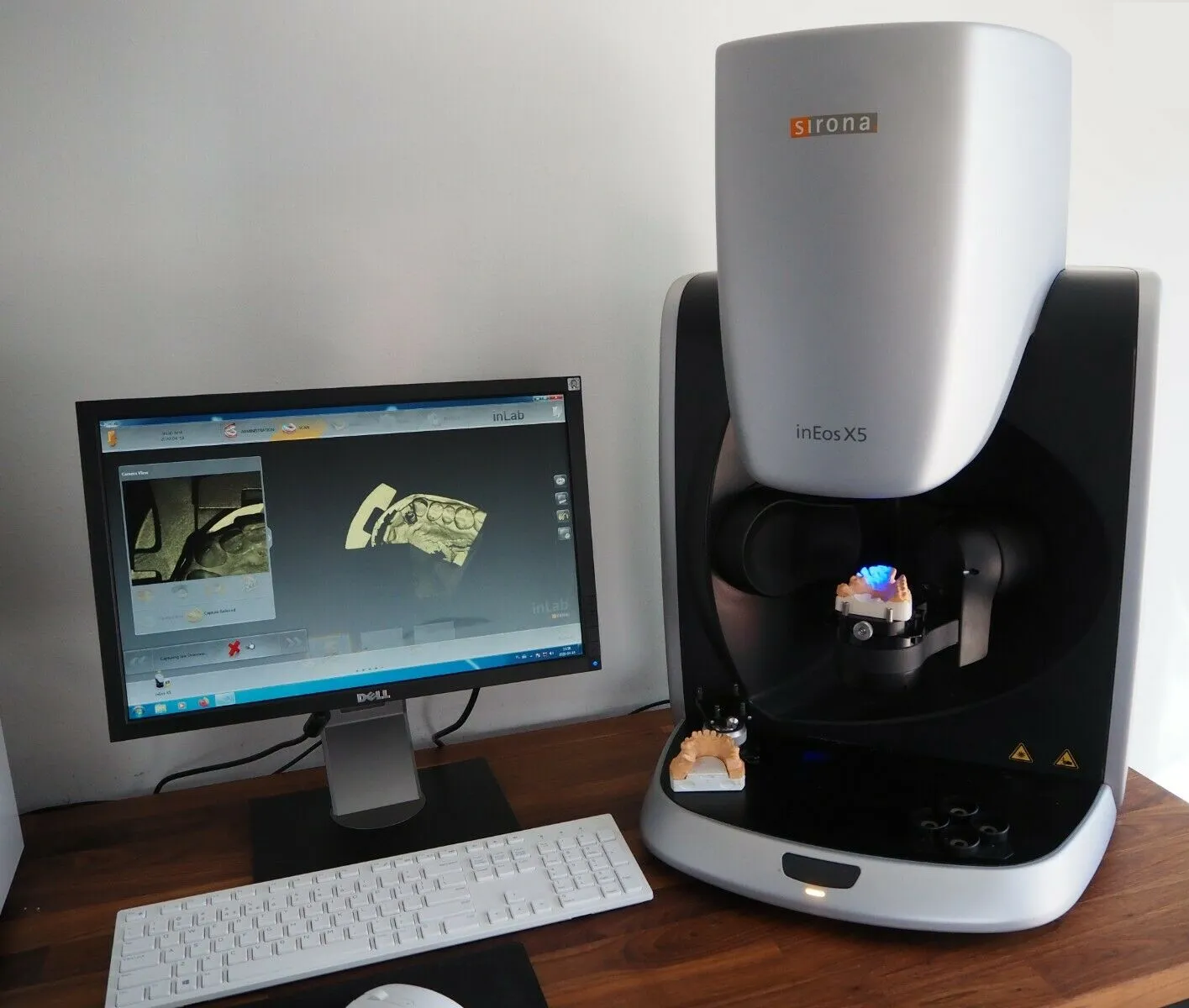

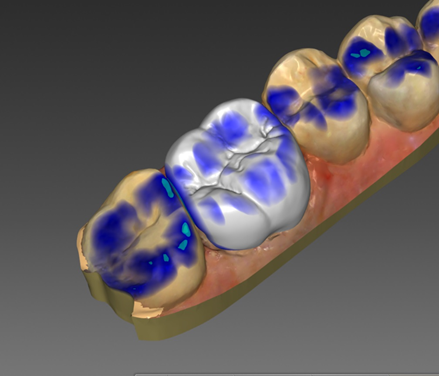

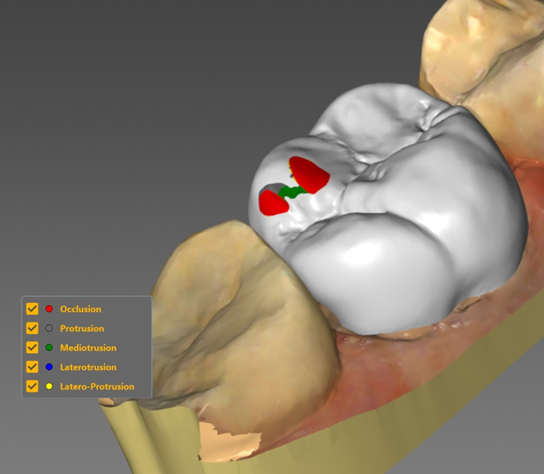

Digital design is similar to “old school” lab work except that each step happens virtually on a computer. Below you can see an example of an occlusion analysis. The colored areas show occlusal pressure. Blue is just out of occlusion, red is in full contact. We adjust the relative arch positions just as we would with stone models

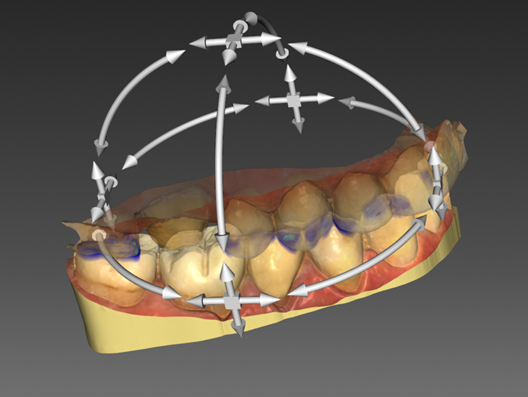

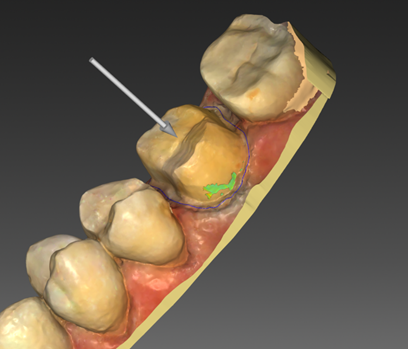

One of the many advantages of the digital workflow is the incredibly high resolution of the scanned data. This is clearly evident in the margin marking stage. We can zoom in to the see the tiniest detail on the prepped tooth, rotate the image at any angle and define margins far more accurately than with hand trimming stone.

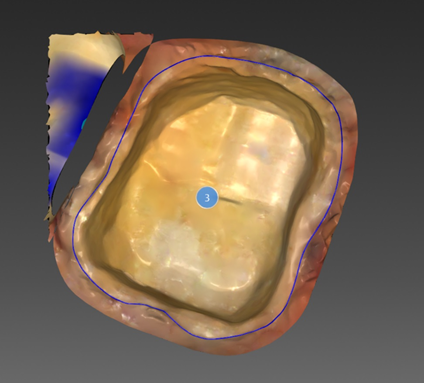

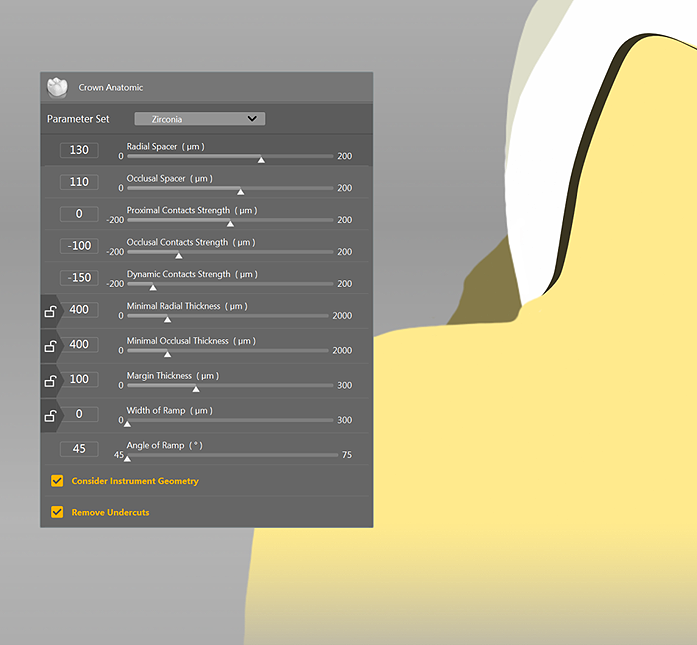

In the digital realm it is simple to adjust the path of insertion and optimize the design to remove undercuts. This assures that restorations seat properly and the glue gaps are held uniformly.

Every design parameter is optimized by material and Dr. preferences. If a Dr. prefers no occlusion, light occlusion or ideal, tight contacts, or light, we can adjust settings accordingly.

Incredibly fast computers with advanced 3d processors have allowed software developers to create design tools that do much of the heavy lifting for initial proposals. The crown in this photo was essentially designed by the computer (with some expert guidance). Artist touches in the anotomy are easily added at this stage. Occlusion and contacts are further optimized to Drs. preferences.

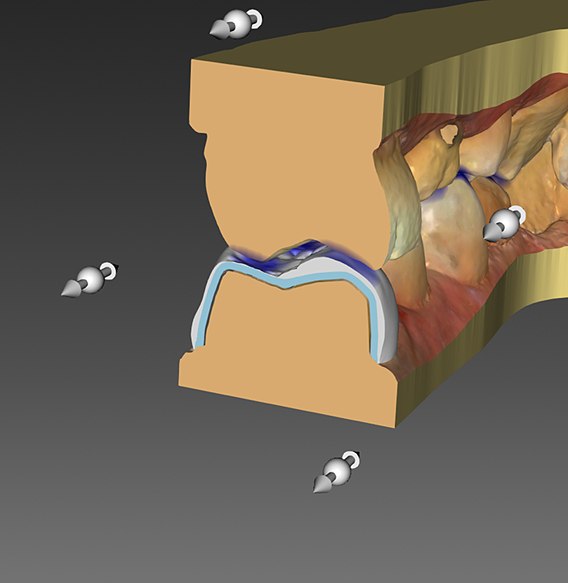

One of the most amazing tools available to the digital designer is examining function. This picture shows a “slice” view allowing insight into proper cusp to fossa relation.

With a digital model it is also possible to quickly calculate articulation of the restoration. All 4 compass movements on a high end lab articulator can be simulated. In the photo above you can see protusion and mediotrusion contact in addition to occlusion. This can be adjusted in the design phase reducing adjustments in chair. Every restoration at DDentLabs is checked with this tool before we mill.

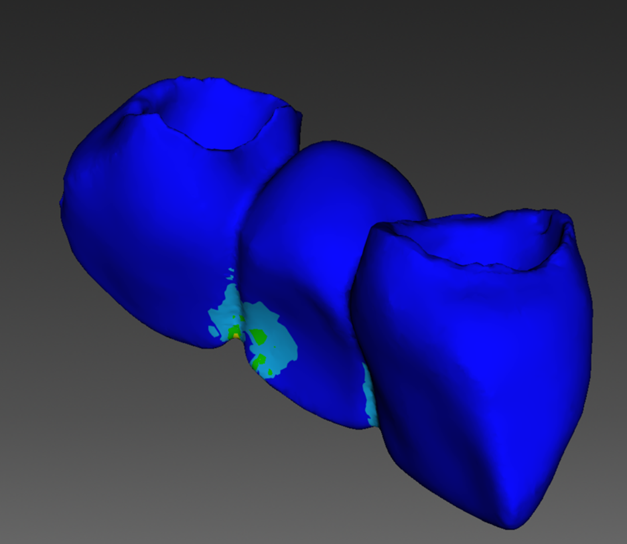

Digital models and fast powerful computers bring something that was unimaginable 10 years ago. Mechanical finite element analysis (FEA) is a tool used by mechanical engineers to predict when critical parts in a jet engine or a bridge will fail. When applied to dental restorations, it can predict when a connector is too weak. This lets us modify the design to optimize strength and cosmetics. We use this tool for every bridge design.

We have made the choice to only offer the very highest quality materials to our clients. For zirconia, this means Katana UTML/STML and Cercon XTML for high translucency and strength (Both multi-layer). We have sampled and tested dozens of other zirconia brands and none come close to the consistency and cosmetic quality of Katana and Cercon.

We pride ourselves on the cosmetic excellence of our standard restorations. They are on par with many of the best hand layered artisan work. This is a result of the high quality materials and our finish techniques. We have mastered the process of using green state infusion stains prior to sintering and then hand finishing with traditional glazes. This combination gives amazing translucency and internal detail of fossa and craze lines similar to expensive hand layered crowns.

We also offer cutback hand layered restorations for additional translucency and characterization.